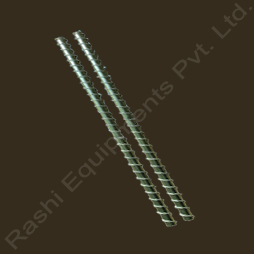

It is maintenance free, non – electric, hassle free device, which mixes the ink continuously & constantly. It is a metal device in cylindrical shape with magnet at both of its end it is installed in the ink tray in such a position that it touches the printing cylinder constantly.

When the printing process starts & the printing cylinder starts rotating it also starts rotating as it touches the cylinder constantly with the help of magnets at the both of its end. Hence it mixes the ink continuously & constantly without using electricity or any other kind of expensive power.

- Length of magnetic ink mixing roller & printing cylinder should be proper. The Magnetic ink mixing roller can be smaller than printing cylinder but in no case the printing cylinder should be smaller than magnetic ink mixing roller.

- After every use, the ink mixing roller should be cleaned with ethyl. NOTE:- Doing so will allow extra ink to get settled on it and the weight of the ink mixing roller will increase causing its sink in ink tray.

- The cleaning process of ink mixing roller should always be along the direction of its rope and not like from top to bottom like a straight line. This will help in maintaining the parachute rope in its original shape and will also not allow the rope loops to get collected un- uniformly.

- Make sure that the ink mixing roller does not fall from operator’s hands otherwise its caps will be damaged and it will bend.

- After cleaning process is over, it is advisable to keep the ink mixing roller horizontally and not vertically in order to prevent the possibility of its getting fallen.